Last month we started a 3-part series on what is arguably the greatest and most versatile tool man has ever created: the ax.

In our first installment, we covered the history of the ax and why/when you might choose to use one over a chainsaw, as well as offered an overview of the different kinds of axes and their anatomy.

After reading that primer, you may have decided it was time you got an ax for yourself.

The “right” ax for you is the one suited to your particular needs. But how do you know which one to pick? Once you start looking for axes on the market, you quickly realize that there’s a seemingly infinite variety to choose from, and a whole lot of opinions as to which is best.

To cut through the clutter, I talked to ax expert Brett McLeod. McLeod is a lead instructor at the Adirondack Woodsmen’s School at Paul Smith’s College, the author of The Woodland Homestead, and the owner of a venerable first name. Below he’ll help walk us through how to choose the “right” ax for you.

Considerations for Buying an Ax

Antique or New

The most important part of an ax is the head. To function efficiently, its bit must be sharpened to a keen cutting edge — thin enough to bite into the wood, but thick enough to resist chipping and breaking. And the ability to achieve this keen cutting edge is dependent on the quality of steel the ax head is made from. You can replace handles rather cheaply if they’re crappy and break, but if your ax head is made of shoddy steel, there’s not much you can do with it except sell it for scrap.

It’s for this reason Brett recommends rummaging through antique stores or barn sales to find an ax, rather than buying one new. “To make a good ax, the head needs to be made from steel that has the right amount of carbon in it. In the old days they were using high carbon steel.”

Nowadays, Brett says, most of the new axes that you’ll find at the hardware store are made in China with metal that comes from “melted down cars, or industrial equipment, or whatever is going through the smelter that day.” This type of low-quality steel tends to either be very soft, rendering it incapable of holding an edge, or very hard, making it prone to chip. This is why Brett advises folks “to buy an old ax and fix it up.”

Buying an older, used ax will not only increase the chances of it having a primo head, it’ll probably save you a lot of money too. You can find old axes at flea markets or antique stores, but Brett says the best place to the find them is in old barns — particularly the corners of old barns: “Oftentimes there’s a barn sale and someone hasn’t actually planned to sell the ax, but it’s sitting there in a corner. I just make an offer and the seller usually accepts. I’ve bought lots of axes that way.”

If you decide to buy an old ax, don’t worry if the handle is shot to hell. Remember, the handle can be replaced cheaply and easily. It’s the head that we’re after. “You’re really interested in a good quality head that hasn’t had a lot of the metal chipped or ground off,” says Brett. If the ax head just has some small chips or is a little rusty, that can be fixed and cleaned up. Don’t be turned off by that. However, you’ll want to pass on old ax heads that are worn down beyond repair. “The most common use or abuse you’ll see in an old ax comes from using it to chop a root in the ground,” Brett told me. “The top edge that’s called the toe of the ax, will oftentimes be worn right down to the point that nothing’s left. That can’t really be repaired.”

For more information about how to tell if an old ax still has life in it, and how to restore one to its former glory, read our in-depth article on the subject.

If you decide to opt for a new ax, Brett recommends avoiding the ones at the hardware store and instead only buying from a few select brands that have a reputation and history for putting out quality tools. A few brands that he recommended included Gransfors Bruks (made in Sweden) and Ox Head (made in Germany). Snow and Nealley is a Maine-based ax company that’s also worth taking a look at. About ten years ago they quietly shifted ax head manufacturing to China and, consequently, their quality went down. After customers made a lot of ruckus, they moved manufacturing back to the US and things have improved.

With all of these brands, you’re going to pay a premium. But as the old saying goes, “Buy once, cry once,” meaning you’re better off spending a lot upfront for quality than constantly having to fix and fuss over a crappy ax that doesn’t perform as well when put to work. Look to spend at least $150 for a boy’s ax (this refers to a size even grown men can use — more on this below) and up to $400 for a full-sized felling ax.

Single Bit or Double Bit

At the end of my first article about axes, I argued that for most guys, a single-bitted ax is the way to go. While it is the most common household ax, according to (the other) Brett, if you’re looking for the most bang for your buck, get a double bit. “If I could carry one ax I would probably carry a double bit,” Brett told me.

While the single-bitted ax can certainly cut faster because of the added weight that comes with the poll (the end of the ax head opposite the blade), Brett recommends the double bit for its more balanced swing and versatility. Its balance is due to the fact that both ends of the head are of equal length and weight. Consequently, when you swing a double-bitted ax there’s less wobble, which means more accuracy, which in turn leads to more efficient cutting. Control, rather than power, is the real key to chopping wood.

And because a double-bitted ax has two cutting edges, it opens up opportunities to create multiple cutting edges for different needs. So instead of having several kinds of single-bitted axes for various kinds of tasks, you could just have one double-bitted ax. As Brett explains, “You can have one bit that you can do dirty work with (limbing, cutting roots), and the other bit for felling,” or “you can file one side for cutting soft wood, and the other side for cutting hard wood.”

Besides providing multiple cutting options within a single ax, a double bit can also serve as a “play” ax. At the Adirondack Woodsmen School they play lumberjack games, including ax throwing. “You can’t throw a single-bitted ax because it’s not balanced. It won’t spin in the air,” says Brett. But because a double-bitted ax is balanced, it’s perfect for throwing. Thus, a double-bitted ax can be both your work and play ax. Even more versatility from an already versatile tool!

While Brett extolled the virtues of the double bit, he did emphasize that whether you go with a single bit or double bit is a matter of preference. One thing to keep in mind (as we’ll see in our next article) is that because it has two cutting edges, double-bitted axes require a bit more situational awareness and safety consciousness than the single bit variety.

Weight of the Ax Head

Another factor you’ll want to consider when selecting an ax is the weight of the head. “Most guys want the heaviest ax possible because it produces more force. It’s why we’re using ax heads that weigh six, six and a half, and even seven pounds in cutting competitions,” says Brett. But for the beginning ax-man and for everyday use, Brett recommends using an ax head that weighs no more than five pounds. While the heavier ax heads provide more force, you lose accuracy in your swing.

Many experts recommend starting off with a 3-lb head on a full-size ax and a 2-lb head on a “boy’s ax.” As you get stronger and more experienced with the tool, you can bump up in weight.

Length of the Handle

While most men would prefer an ax with a longer handle because it allows you to swing with more force, Brett says that it’s actually better to go with a handle that’s shorter than you’d think you’d need. “The longer the ax handle the more force you could deliver theoretically, but there comes a point in that length where you’re not able to control it as well, and so it doesn’t matter how much force you have because you lose things like the proper presentation of the ax bit to the wood.” You’re looking for the sweet spot between force and accuracy, and for the beginning ax-man in particular, shorter handles will offer the control needed for efficient cutting.

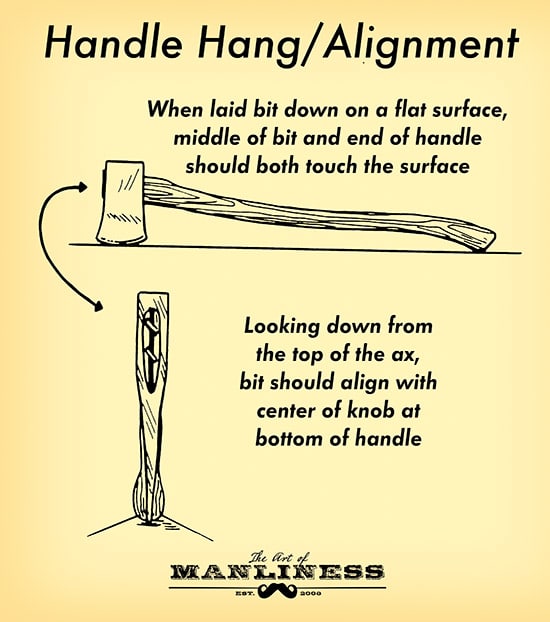

The length of a handle is typically (but not always) measured from the top edge of the ax down to the knob at the bottom. Handles come in two standard lengths — full-sized (or felling) and “boy’s ax.”

The standard length for the handle of a felling ax is 36”, but Brett says that’s even too long for most men. Instead, he recommends a 31” handle for your average six-foot-tall male. This length will provide you with both force and control.

While many men are intent on getting a full-sized felling ax because of its storied history, if you’re not planning on using it to split firewood (a job for which a maul is really better suited) or doing lumberjack competitions and heavy forest work, Brett actually recommends getting an even shorter “boy’s ax” handle. Despite the name, its 28” length is appropriate and even ideal for the average grown man. Sure, the boy’s ax doesn’t have the same “oomph” as its full-sized brother, but for most chores a suburban man would do around his home or out in the woods camping, it will get the job done, and allow you to swing with more control. You can get both single-bitted and double-bitted axes with a boy’s-length handle.

Handle Material

A lot of the ax handles you’ll find at the big box hardwood stores are made from plastic, but Brett says you always want to go with a handle that’s made from wood. Specifically, hickory or ash. Brett’s preference is hickory, but ash will work just fine.

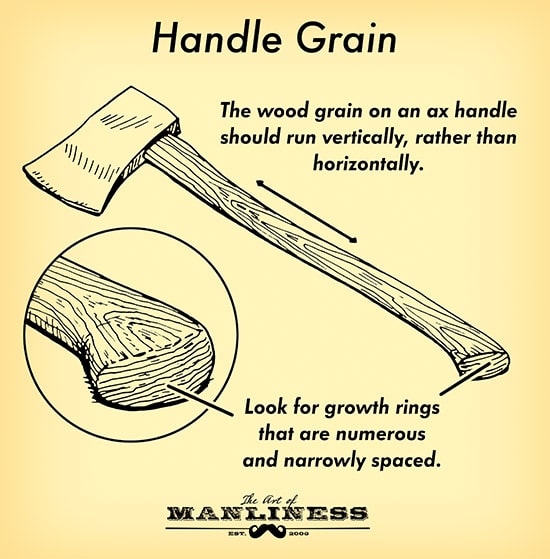

After you’ve ascertained the handle is made from hickory or ash, you’ll want to inspect the grain direction of the wood, as well as growth-ring width and quantity.

Ideally the grain of the ax handle should run parallel to the bit of the ax. Handles with grain that runs perpendicular to the bit tend to be weaker and may snap when you strike a tree.

The growth rings in the handle’s wood should be tight, numerous, and narrow. Wood with this pattern is much stronger than wood with fewer, broadly-spaced growth rings.

Curved or Straight Handle

As we discussed in our first article, ax handles are either curved or straight. Most single-bitted felling axes have curved handles. If you go with a single bit, Brett recommends the curved handle: “Swinging an ax with a curved handle feels a little more natural.”

If you go with a double-bitted ax, your only option is a straight handle, as it’s the only kind they’re made with. If the handle wasn’t straight, you wouldn’t be able to flip the ax around to use the other bit.

No Varnished or “Artisanal” Handles

Brett noted that when you buy axes from the hardware store, the handles are likely going to be varnished. If that’s the case, Brett recommends taking some sandpaper and elbow grease and sanding the varnish off. “Varnish just makes the handle slippery. If you’re using the ax with wet hands, the ax can go flying right out of your hand. You really want to be able to feel the handle and control it, and a little bit of friction is good for ax control.” The only downside with unvarnished handles is that you can develop blisters on your hands, but Brett says with time, you’ll develop some calluses that’ll solve the problem.

While he didn’t mention it specifically, this bit of advice would also seem applicable to the “artisanal” axes out there that have painted handles, ala the Best Made Co. The painted parts would likely slip more in your hands, though such axes are largely purchased as decorative pieces rather than working tools anyway.

Conclusion

For such a simple tool, there’s a lot to consider when purchasing an ax. But if you take the time to find the right one for you, you’ll have a tool that will provide a lifetime of useful service. Heck, if you take care of it, you can even pass it on to your son, and he to his son.

In our conclusion to this series on the ax, we’ll discuss how to swing an ax and use one safely. Until then, keep your bit sharp and stay manly!

Read the Series

History, Types, and Anatomy of the Ax

How to Choose the Right Ax for You

How to Use an Ax Safely and Effectively

__________________

Illustrations by Ted Slampyak

My thanks to Brett McLeod for his tips and advice. If you’re interested in learning lumberjack skills while earning college credit, be sure to check out the Woodsmen’s School at Paul Smith College!